Technology advances have brought along the creation of new business concepts such as transformational logistics, digital ecosystems, and logistics 4.0 or smart logistics; all of which aim to make the supply chain processes more efficient while meeting the needs of clients in the best possible way.

Switching from traditional logistics to transformational logistics consists in using technology to develop a smart supply chain that focuses on the clients and is connected to, and enables integration with, other interfaces and guarantees a tailored service, a better forecast of the demand, a decrease in inventory, an increased route optimization and geolocation, and a better traceability of shipments, among others.

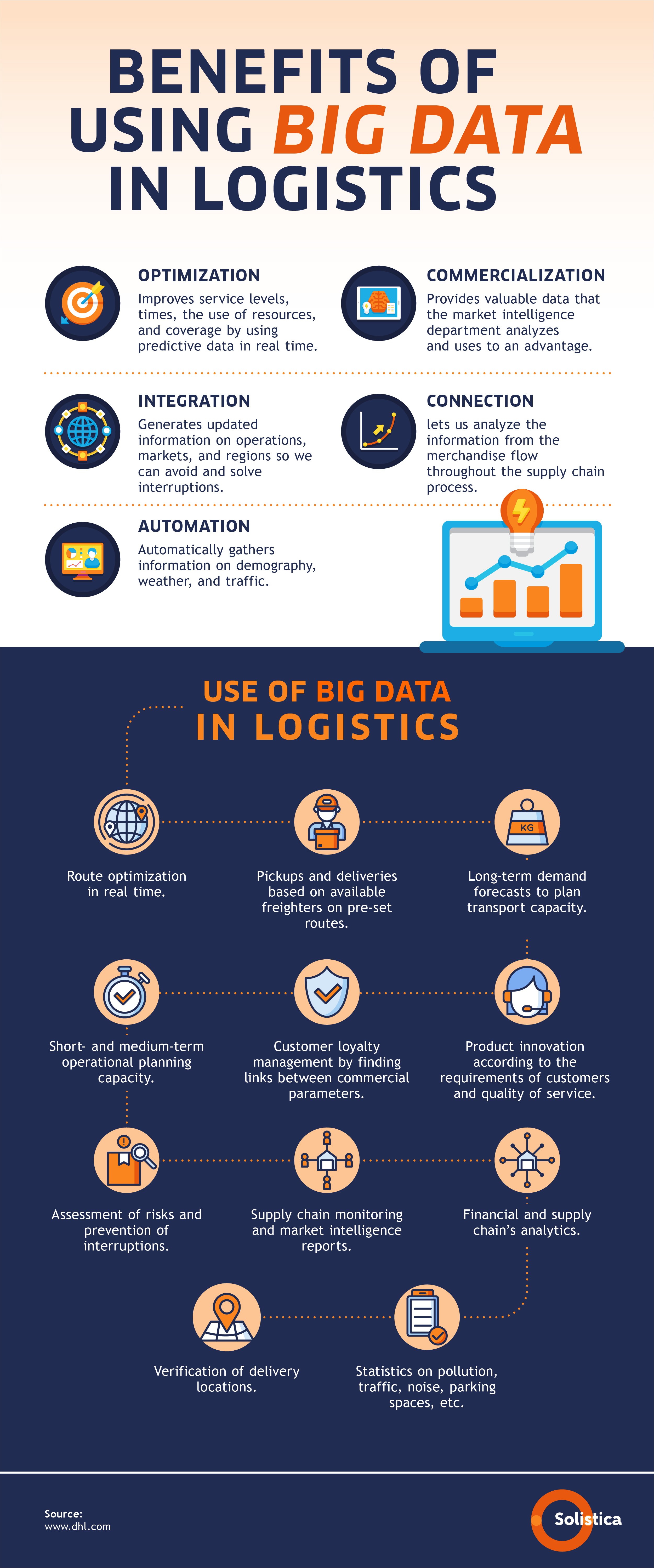

Transformational logistics arise from the undergoing evolution of logistics in terms of digitalization where, among many other issues, we contemplate the use of drones and self-driving vehicles to help expedite the delivery of products in hard-to-reach locations; big data to build transport routes from the cloud and keep track of vehicles and products in real time; blockchain to create a permanent record regarding the transportation of merchandise; and robots to automate the storage processes and order preparation.

Apart from capitalizing on the knowledge we gain from using these technology trends, transformational logistics aim to share the practices and processes of diverse industries by offering comprehensive solutions. In the article published by Expansión magazine in Mexico “Transformational Logistics, an adjustment to the rules of the game” Solistica explains how this novel concept is already being put to good use in some logistics processes.

The companies that wish to implement this new and sustainable philosophy must consider some points before switching from traditional logistics to the digital ecosystem that will help them become disruptive in their sectors:

- Innovation along their supply chain, but especially in the last mile, and always minding the traditional retail model.

- Go from the idea that efficiency is more important than time and embrace the notion that both issues are equally important.

- Avoid using legacy and obsolete information systems that were designed exclusively to respond to the needs of a conventional commercial environment. We need platforms that match the omni channel environment in terms of planning, managing, and executing.

- Learn how to combine product tailoring and process standardization. The former increases the level of service and the latter decreases costs dramatically.

- Invest in new models first and then make them profitable instead of overanalyzing profitability before making investments.

- Create new strategies for the last mile that consider new means of transport and supplement existing strategies.

Companies that make the best use of technology trends for their transformational logistics have started to create sustainable solutions that benefit industries:

- Cooperative models that enable the optimization of cargo by sharing expenses among members of cooperatives or participating companies.

- Raise consumers’ awareness regarding the delivery capacity and considerations of time and costs.

- Ecological measures to ensure shipments have the lowest possible ecological footprint, and other green logistics’ measures.

- Cooperation and negotiation with companies that might solve the needs arising in the last mile.

Some companies have embraced this novel transformational philosophy and have first-hand knowledge of the operational needs of their clients’ logistics ecosystems; detecting and sharing best practices and trends of diverse sectors with an increased visibility.

Through technology, they offer safety and trust in processes that have a positive impact on the productivity of the supply chain and of the whole company.

By adapting to new realities, Solistica makes the best use of its experience with technology to change the way it carries out logistics; designing and offering comprehensive, sustainable, adaptable, and accessible solutions to its clients.