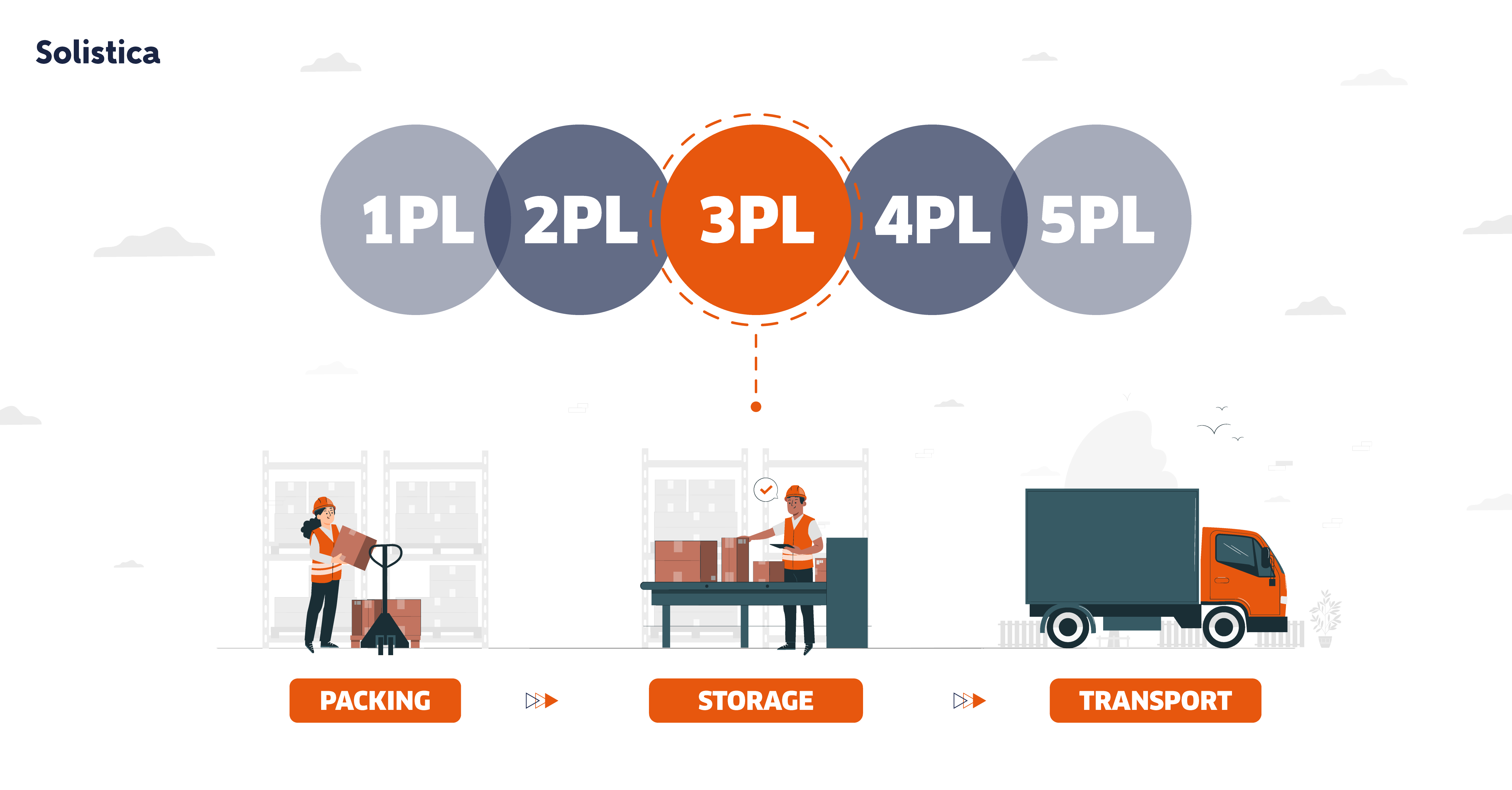

Outsourcing logistics: the complete guide on 1PL, 2PL, 3PL, and 4PL operators

Have you ever wondered how all those online shopping packages arrive at your doorstep? Behind each delivery, there is a complex network of logistics-specialized companies that handle the transportation, storage, and distribution of products. Welcome to the fascinating world of logistics outsourcing!

Third-party logistics operators, also known as 3PLs, are external companies hired by other businesses to manage part or all of their logistics operations. This includes activities such as goods transportation, warehouse management, order processing, route planning, and much more. The goal of outsourcing these services is to optimize processes, reduce logistics costs, and focus on the core business.

On the other hand, there are the 4PLs, which correspond to the “Lead Logistics Providers”. These are companies that design, plan, and coordinate the entire supply chain of their clients using advanced technologies. They act as intermediaries between the company and the various 3PLs, choosing the most suitable ones for each operation. In this way, the 4PL allows for the integration and optimization of all logistics from start to finish.

In contrast to these models, in a 1PL scheme, the company manages its logistics internally, while the 2PL corresponds to situations where only a part is outsourced, such as transportation or storage. The current trend points towards greater outsourcing of these activities in search of higher efficiency.

1PL Operators: basic logistics at the local level

Imagine a small local company that sells its products in the area and takes care of distributing them itself. This is the typical 1PL or First Party Logistics model.

1PL companies are self-sufficient in logistics, meaning they have their own means of transportation and directly handle the mobilization and delivery of their products to nearby customers in a basic, uncomplicated way.

However, they sometimes subcontract transportation services with external companies to support their local distribution. These are called 1PL providers.

For example, a local bakery that distributes freshly baked bread around the area with its own van would operate under a self-sufficient 1PL model. It only outsources transportation services if it requires support to supply some specific, more distant businesses.

This basic logistics system is ideal for ventures with limited geographic distribution. But it has the drawback that it does not easily allow for expansion to other areas or cities.

2PL Operators: the first step towards outsourcing

What happens when the business grows and the company needs to distribute to other cities or countries? That’s when 2PL or Second Party Logistics operators come into action.

2PL companies function as strategic partners, taking care of transportation to more distant destinations where the manufacturer cannot reach on its own. However, storage, picking, and inventory management are still the responsibility of the producer.

This is then a partial outsourcing of logistics, focused mainly on the shipment of goods.

The 2PL operates as a partnership focused on the bulk shipment of goods to other regions or countries where the brand operates. In this way, the producer can concentrate on manufacturing, while partially outsourcing transportation on long-distance routes.

However, under the 2PL model, inventory and warehouse management is still the responsibility of the contracting company. There is not yet a full outsourcing of logistics processes.

3PL Operators: Complete outsourcing of logistics

When we talk about logistics outsourcing, we usually refer to 3PL or Third Party Logistics operators. They are in charge of managing and executing most of the operations of the supply chain, among which stand out:

- Storage and inventory control

3PLs manage warehouses and distribution centers where they store their clients’ goods. They handle both their own facilities and rented spaces, and take care of tasks such as product reception, location, order preparation, and dispatch coordination.

In addition, they keep a computerized control of the stocks, recording in real time every entry and exit from the inventory. This allows visibility over stock levels and informed decisions about replenishments and movements between warehouses.

- Order preparation (picking and packing)

When an order arrives, the operators locate the products in the warehouse, extract them from their location (picking), and pack them appropriately for transport (packing). The preparation of each order can involve from one to thousands of different items.

Many 3PLs invest in technologies such as automated picking systems, barcode readers, and intelligent routing algorithms. All this makes the preparation processes faster and more efficient.

- Transportation and distribution of goods

The outsourcing of transportation is one of the main incentives to hire a 3PL. They are responsible for moving the products between logistics centers, or directly to the final customer.

They have their own fleets of trucks and alliances with other carriers. They optimize routes, modes of transport (land, air, sea), and take advantage of economies of scale.

- Delivery tracking

3PLs allow monitoring at all times where each order is, thanks to the scanning of barcodes and RFID at each step, and integration with transportation systems.

Customers can check the status of their shipments in real time and have visibility from start to finish on orders. This provides peace of mind and improves the user experience.

- Reverse logistics

It covers the management of returns and warranty processing. The operators receive the returned products, verify if they proceed, and coordinate the repair, replacement, or refund. They also take care of the transfer to the warehouse and re-entry into stock.

This reverse logistics service unloads companies from complex tasks and allows them to focus on sales.

In summary, 3PL outsourcing aims to improve the efficiency of the entire supply chain, reduce logistics costs, and free companies to do what they do best: produce and market their products.

Basically, the 3PL logistics operator functions as a strategic partner that allows the manufacturer or distributor to focus on their expertise (produce and sell) while outsourcing logistics processes to a specialized company. It’s that simple!

This outsourcing promotes efficiency throughout the chain.

4PL Operators: Integral managers of logistics networks

Even for large companies with globalized operations, managing the entire distribution network can become very challenging. For this, 4PL or Fourth Party Logistics operators emerged, also called LLP (Lead Logistics Providers).

4PL or Fourth Party Logistics operators go even further, functioning as integral managers of the supply chain through outsourcing.

4PLs function as logistics controllers, taking care of the design, planning, and strategic coordination of the different 3PL operators in each region. They optimize the flow from start to finish by integrating the best providers of transportation, storage, order preparation, and last mile on a centralized platform.

In other words, a 4PL company is responsible for selecting and hiring the best transportation, storage, order preparation companies, etc. Then, it manages them centrally to ensure maximum efficiency at each link in the distribution chain.

Thus, thanks to outsourcing with a 4PL operator, any business can completely outsource its logistics at the highest level, freeing up resources to focus exclusively on boosting its sales.

As you can see, logistics outsourcing through 1PL, 2PL, 3PL, and 4PL operators provides a great competitive advantage to companies of any size and sector to focus on what they do best. Implementing an outsourcing model adapted to your needs could catapult your business to the next level.