Every now and then, newly minted terms pop up describing specific practices in logistics’ operations. Here is one that has been gaining momentum: Backhaul, a.k.a. backloading.

Backhaul refers to returning a vehicle to its original starting point, and logistics applies this term to define return trips carrying useful loads. In other words, it basically consists in not scheduling empty return trips.

Backhauling implies planning return trips, tracing the routes meticulously for the transported goods in each segment of the trip, and – essentially – foresee everything so trucks do not return empty and thus, maximize productivity.

How do we do this?

The idea is simple: the unit will carry out deliveries normally but stopping on its way back at companies needing to return stock or packaging to the distribution center or at the facilities of suppliers of raw materials.

From a logistics point of view, it means planning return trips and trace routes to make sure goods are transported in each segment. This improves the use of vehicles and drivers, increases productivity, and eliminates the needs of additional trips, which results in a reduction of fuel waste.

The most important aspect of setting up a backhaul strategy is to plan the delivery and pick up routes well. These must be optimized so they can be efficient. Once a delivery route has been set, we notice which suppliers are nearby so trucks can pick up goods at those sites without much detouring.

Using fleet management systems to plan routes and GPS tracking are also helpful because they allow senders to accept jobs faster thanks to the information they yield on space, locations, and available hours.

This synergy demands previous planning. For example, we can find out what is our backhauling capacity by defining the available capacity in each distribution center, their range (distance in miles between distribution centers), and analyzing what type of goods return to these centers (stores may want to return pieces they cannot sell like pallets or furniture.)

Backhauling is common among seasoned logistics companies with enough technology and infrastructure to carry out and schedule trip planning. This is a win – win situation for clients and logistics companies.

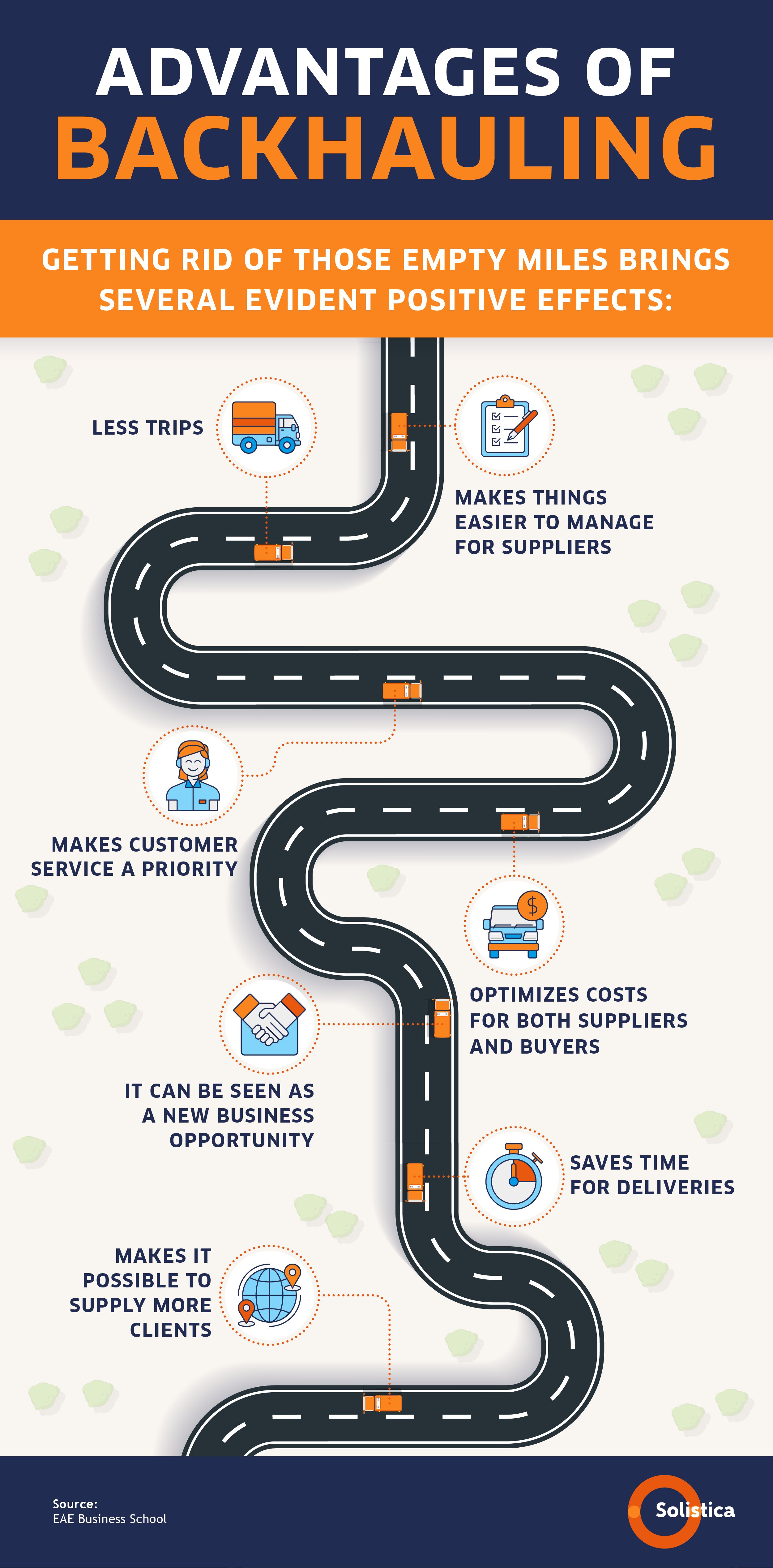

The benefits of backhauling go beyond planning the trips of trucks to complete a segment a time. Planning the shipments efficiently avoids fuel waste, which translates into savings and lower environmental damage. It also improves the operational efficiency by maximizing the use of units and labor, which in turn improves productivity and increases profits.

This operational practice has been increasingly adopted by Latin America’s logistics companies, improving the quality of their offer and contributing to the sector’s logistics competitiveness.

*This blog was originally published on December 20 2018 and modified on April 20 2022.

*This blog was originally published on December 20 2018 and modified on April 20 2022.