One of the advantages e-commerce offers to clients is the chance to return products that failed to meet their expectations; this has forced those involved in the supply chain to improve the speed, efficiency, and cost of their reverse logistics.

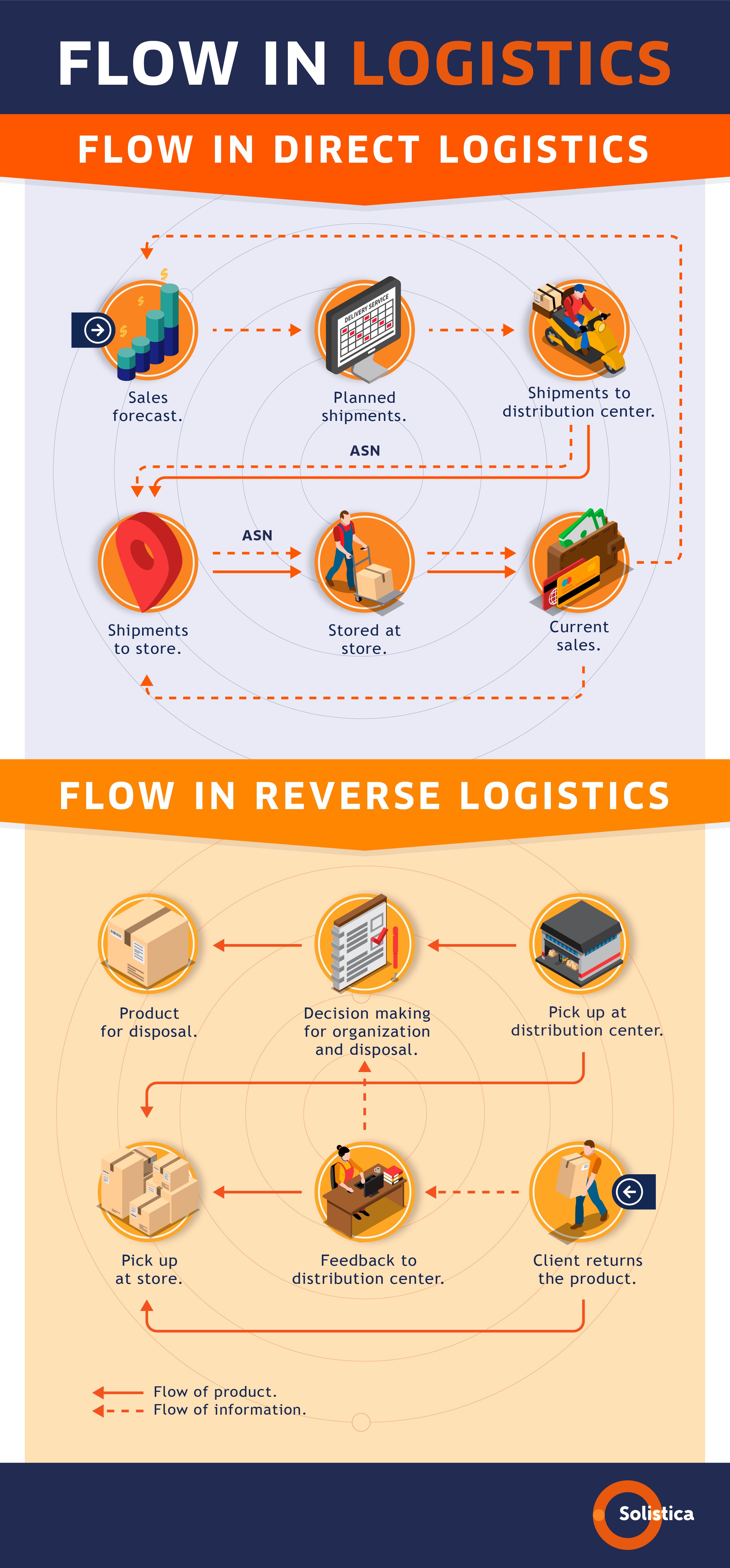

Reverse logistics consists of all the operations related to reusing products and materials, including planning, implementing, and controlling the flow of raw materials and finished products from consumers to point of origin with the intention of recovering their value, at least partially, or dispose of them properly.

Because of their profit margins, grocery retailers were first to realize the impact that reverse logistics has on customer service and overall costs. Even though reverse logistics has gained ground in the past years, there are still many companies not using it to their advantage; in fact, research on this topic has evolved during the past two decades, only.

Any process that happens after products are delivered implies reverse logistics. Generally, companies do not start reverse flows as part of their planning but as a response to actions carried out by clients or members of descending channels. Either because the product is defective or because the client is not satisfied, the manufacturer or retailer should set up the return shipment, test the product and decide whether to disassemble and repair, recycle, or dispose of it.

Reverse logistics is more than just reusing containers and recycling packaging materials; it also involves processing goods returned due to damage or because they weren’t sold, restocking, recovering assets, managing excess inventory, recycling programs, managing dangerous materials, and getting rid of obsolete equipment. In addition, it offers direct benefits:

- Improves the satisfaction of final customers by letting them return products.

- Lowers the investment in resources.

- Lowers the costs of warehousing and distribution.

Because of the nature of its processes, it is more likely for retailers to accept returns than it is for manufacturers and, according to the circumstances of the products, they can send it to their central facilities for processing, resell it as is, repackage it and sell it again as new, manufacture and furbish it anew, sell it to other supplier, sell it at discount stores, recycle it, donate it to charity, or dispose of it in a landfill.

Reuse and recycle aren’t new destinations for returns. Deposits for plastic containers and junk metal peddlers are an example that they have existed for a long time.

Strategies some companies follow to improve their reverse logistics

Looking to remain competitive and increase the loyalty of clients, some companies are making their return processes and policies easier, keeping in mind the satisfaction of customers. For example:

Set new return policies according to the product’s price or time:

- 30-day return window.

- To replace low-cost products, suppliers no longer ask for a return because the shipment is more expensive than the product.

Foster greater collaboration between manufacturers and retailers:

Previously, manufacturers accepted all returns because they feared losing position in the market if they refused. Today, they compensate retailers and wholesalers for clearing their products because this service of reverse logistics, for them, improves their recovery rates and automates the process of disposal. At the end, this collaboration frees the manufacturer of all additional responsibility.

Take advantage of data to optimize processes

Every day more manufacturers choose to hire logistics companies to manage, prevent, organize, process, resell, dispose of, or clear their return products using many different data such as volume, conditions of the products, reasons for the returns, and sales. Basically, they search for a partner to manage their reverse logistics while they focus on tasks related to their core business.

Other companies are hired to check, solve, or repair products on the field, minimizing thus the number of returned products.

Implement a Do it Yourself model

Some manufacturers of electric and electronic devices are starting to send easy-to-replace components so clients can repair their products themselves without the assistance of technicians.

Expand the facilities

A good strategy for improving the efficiency of the returns has been opening collection or return centers close to customers. For online shopping, allowing return at brick-and-mortar stores can result in savings for both suppliers and customers.

The volume of returns has risen hand in hand with e-commerce; therefore, companies need to find ways to “filter” them, most of all those with high operation costs.

Manufacturers and retailers constantly train their customer service department to make the return process more efficient. Furthermore, they invest great amounts of money in technology like bar codes, automated monitoring, automated returns, electronic data exchange, and radiofrequency but, sometimes, this is not enough.

Logistics companies like Solistica offer reverse logistics solutions to make operations more efficient with adequate technologies and processes, which translates into a better experience for customers.