For logistics, storage means not only safekeeping products in a physical space, but also controlling and resupplying the stock; therefore, together with transportation, it is considered the core of every supply chain.

The boom of e-commerce has forced companies to outsource some of their logistics operations to specialized companies (3PL), using their experience to improve warehouse management.

“Clients seek logistics operators with the know-how, capacities, infrastructure, and systems they may struggle to gain by themselves since logistics is not their core business,” said Rodrigo Moreno, Solistica Mexico’s Warehouse Manager. “The evolution of e-commerce forces manufacturers and retailers to rely on a logistics operator that masters these processes efficiently so they can satisfy their clients’ needs and keep up with their pace.”

The accelerated growth of e-commerce has led 3PLs to develop new value-added and distribution services to meet and exceed their clients’ needs. With the new business models focusing on consumers, warehouses must also focus on issues like productivity, quality, and continuous improvement.

Storage trends

On-line purchases – with their same-day or next-day deliveries – have fostered the growth of efficiency and optimization strategies focusing on end clients. As Marcio Almeida, Solistica’s Global Director of Warehouse Operations, said: “Warehouses will never go away, they will always exist, but the operations of Distribution Centers will keep evolving and increasingly becoming more efficient, thus allowing us to offer better services; Distribution Centers will become a series of small warehouses designed to benefit end clients and will be operated considering the different distribution channels of the future.”

This optimization of operations’ efficiency cannot be achieved without the implementation of technology tools such as warehouse management systems (WMS) and transportation management systems (TMS), which offer clients the possibility to know the status of their merchandise.

“Our clients ask us to be always aware of what is going on in the warehouse; in other words, they want to know if we have the right productivity levels, if we are shipping correctly, and if we embrace continuous improvement and innovation,” said Almeida.

To achieve this, clients and logistics operators must be aligned and share the same information. Even though tech tools may be owned by the logistics company, the decisions regarding storage and distribution are made by both. As Mr. Almeida explains it: “We own the technological tools, but our purpose is to be one of the strategic branches of our clients. Having these systems gives us the flexibility as operators to adapt the information the client needs and make it compatible with their reports and dashboards of indicators.”

This new comprehensive 3PL model aims to give clients a sole contact point for their diverse logistics processes instead of having a different supplier for every stage: storage, transportation, and value-added services. 3PLs work as integrators of the supply chain, offering clients end-to-end services aiming for operational synergies, improvement of the service levels for end clients, and cost savings through increased productivity.

“Before, clients searched for a storage supplier and then looked for a different supplier for transportation, and another one for outsourced manufacturing. Today, they seek a sole contact point: a strategic logistics partner that offers a comprehensive service portfolio. For example, besides storage services, a 3PL can also offer value-added services in a package. This need of comprehensiveness has increasingly become a must in the market. Clients are now looking to have a complete service chain through 3PLs.” said Marcio Almeida.

Even though most 3PLs have a mission to contribute to outbound logistics processes (activities happening after manufacturing and related to distribution), some 3PLs have started to offer inbound logistics services (internal logistics for manufacturing systems: from materials reception and storage, to supply of manufacturing lines). This trend may turn distribution warehouses into inbound warehouses adhering to the just-in-time philosophy.

Solistica and new value-added services

To optimize the outsourcing of logistics services in Latin America, Solistica has set its innovation strategies aiming to get the best results for its clients in terms of service level improvement, flexibility, and costs. Such is the case of DataPack VAS, a software designed by Solistica and used to manage the logistics of outsourced manufacturing processes (VAS), according to the reality of the region. To learn more about this system, its functions, and its benefits, please read this article: (link to article called Technological disruption in the 3PL model for Latin America).

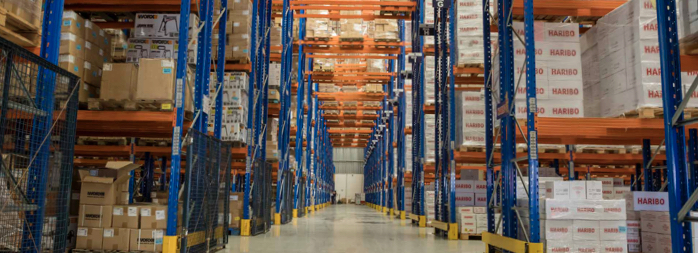

Since its foundation, Solistica has stood out for its attention to details, flexibility, and innovation, which show in its 500,000+ square meters of warehouse space around the globe, in its Intelligence Center where – in alliance with the world’s leading IT companies – technology and software are applied on logistics solutions, and in its monitoring and security centers. This has made the company worthy of certifications such as ISO 39001:2012, ISO 9001:2008, OHSAS 18001:2007, ISO 14001:2004, PREAD, ISO 28000:2008, and the Seal for Best Innovation Practices.

Solistica is an example of how some logistics companies in Latin America have started to adapt to the specific needs of their clients by broadening their portfolios with value-added services to supplement their storage and distribution strategies. For example:

- Labeling: Placing the mandatory tracking, branding, country of origin, barcodes, and customized labels.

- Packaging: Placing the product in boxes, documenting, and classifying. Making space more efficient to access better transportation rates.

- Kitting: Packaging two or more items together and inserting advertising or samples.

- Reverse Logistics: Including managing the return of goods, recovering and recycling wrappings and hazardous waste, and managing overstocking.

- Refurbishing: Collecting returned goods or products with minor damages to restore them and sell them again.

- Palletizing: Hiring pallets and forklifts to lift several pounds or tons.

“The fact clients look for comprehensive logistics companies show they are hoping to have a strategic partner that enables mutual growth, and to have someone who clearly understands their logistics. More than hiring just a service, clients are searching for a long-term, strategic relationship. What operators and clients look for are 8-, or 10-, or 20-year long relationships because there is an understanding and a relationship so strong that you become part of their business,” said Rodrigo Moreno.

Solistica becomes a strategic partner by meeting its clients’ logistics goals and by contributing to their commercial and service goals. Its clients’ end consumers also become Solistica’s clients.