Globalization has forced companies to expedite their warehousing and set up processes in order to maintain their competitive advantage and the loyalty of their customers with efficient response strategies like cross docking.

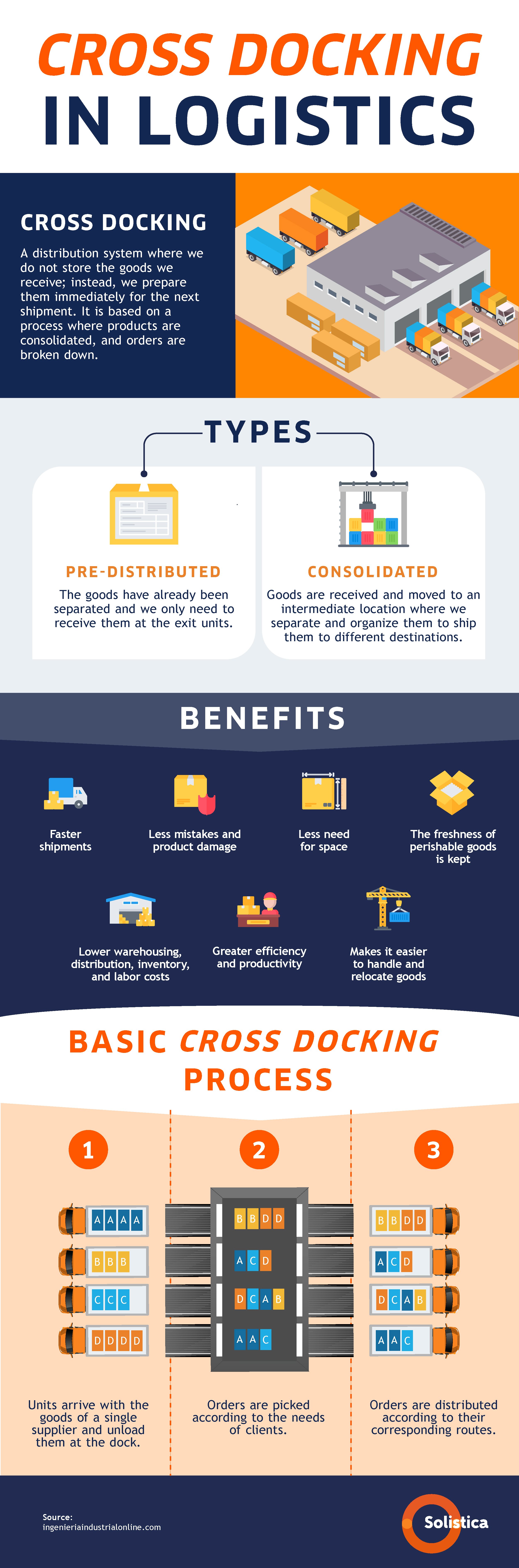

Cross docking is a logistics model that optimizes the supply chain by eliminating or considerably lowering the storage time because the goods are not stored after unloading but instead is prepared and sent almost directly to clients. There are two types of cross docking:

- Direct or pre-distribuited: the goods are already separate and need only be received by the exit units previously organized according to the delivery locations. This is the most basic model since products do not require a lot of handling.

- Indirect or consolidated: the goods are received and moved to an intermediate location or picking area where they are separated and organized to be sent to the different destinations.

The cross docking process

The basic cross docking model is carried out in different stages:

- Units arrive bearing the goods of a sole supplier.

- The orders are picked according to the customers’ needs.

- The orders are distributed according to the corresponding routes.

Benefits

Besides expediting their deliveries and avoid warehousing costs, companies using cross docking get other major benefits:

- Greater efficiency and productivity in the supply chain.

- Lower costs related to warehousing, distribution, inventory management, and labor.

- Easier to handle and relocate goods.

- Easier to keep the freshness of perishable products.

- Greater compliance rate for fixed deadlines.

- Easier to update and greater availability of goods.

- Better organized supply line by managing with stores the needs of clients.

- Less need for space.

- Less mistakes and product damage (due to a decrease in the number of people involved in the process).

In addition, and because it is compatible with postponement strategies (last-minute changes with zero impact on customer service), kiting can be done in transit.

The constant flow of products on which cross docking is based creates savings and expedites the transportation at a low cost; however, we suggest implementing it only when the following characteristics are met:

- Storage time is less than 24 hours.

- Goods are sent to clients or forwarded to the picking process immediately after unloading.

- Technology tools that facilitate an Efficient Consumer Response (ECR) have been implemented.

- The investment justifies the implementation.

- There is an effective exchange of information about products and their statuses.

- There is a common and balanced strategy for the distribution of units.

- There is a commitment among the involved departments.

As you can see, this model involves a process to consolidate products and then breaking them apart in several orders; nevertheless, the move from the picking platform can happen using multiple gathering and delivery methods.

Cross docking focuses on making the best use of business systems and technology to create a just-in-time shipping process. It also eliminates the need to have multiple commercial relationships and lowers the costs incurred by small shipping systems because all the activities can be carried out by the same team.

Cross docking focuses on making the best use of business systems and technology to create a just-in-time shipping process. It also eliminates the need to have multiple commercial relationships and lowers the costs incurred by small shipping systems because all the activities can be carried out by the same team.

Logistics companies like Solistica offer pre-distributed or consolidated cross docking services via training and consulting focusing on achieving the correct coordination and execution thanks to several warehousing, picking, and transportation solutions.

*This blog was originally published on August 12 2019 and modified on May 11 2022.