Cross docking: a transformative logistics strategy

Today, companies face a new competitive landscape. Consumers are increasingly informed and demanding, and they expect to receive their products quickly and in perfect condition. To meet these expectations, companies must optimize their logistics processes to reduce costs, improve efficiency, and provide better service to their customers.

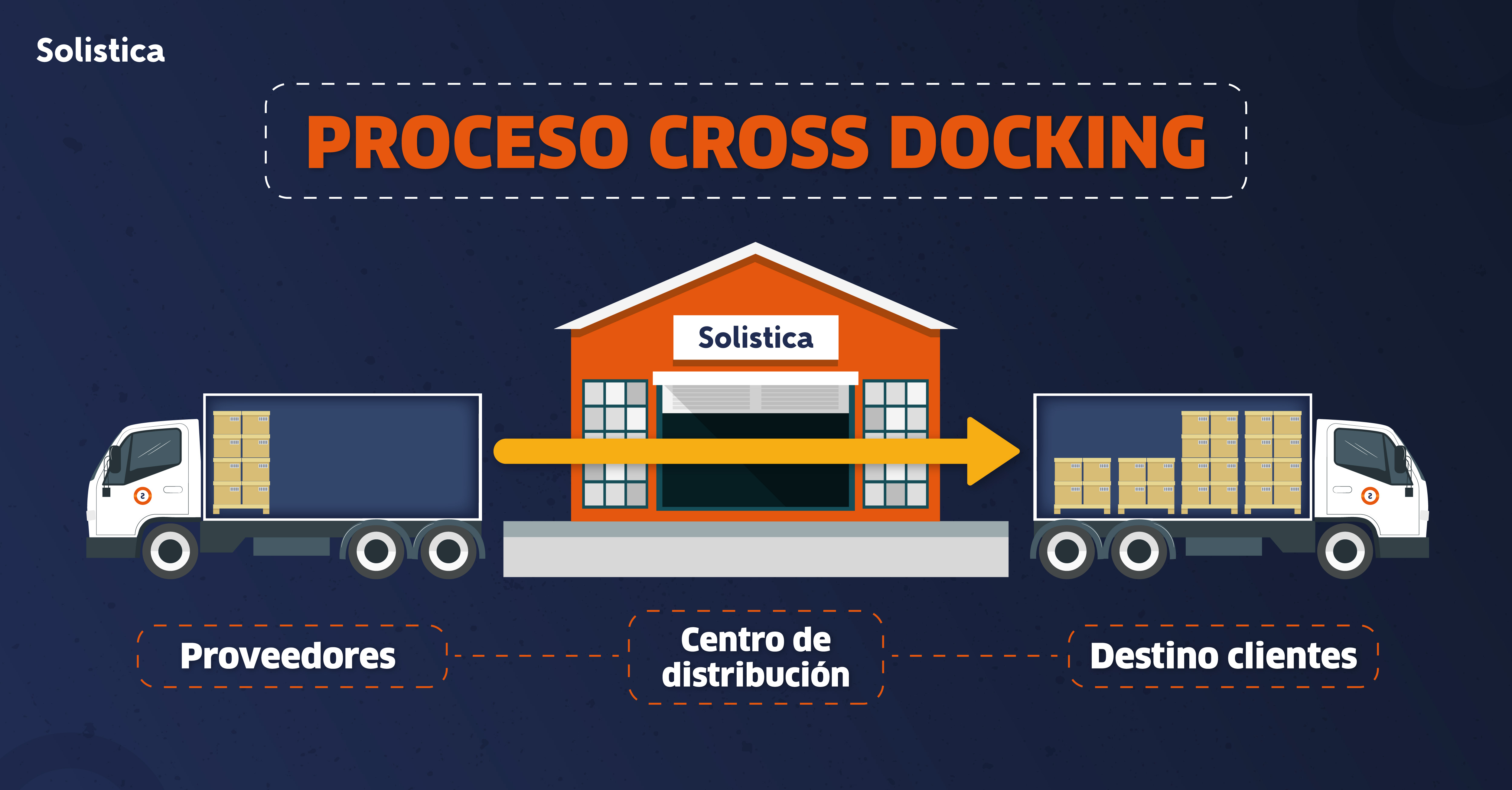

In this context, cross docking emerges as an innovative logistics strategy that offers numerous benefits. Cross docking, or dock crossing, is a logistics strategy that involves receiving merchandise from suppliers, preparing customer orders, and distributing them directly to their destinations, without the need to store them in the company’s facilities.

How does cross docking work?

Cross docking can be divided into three main phases:

- Receipt of merchandise: Products arrive at the cross docking facilities from the suppliers. In this phase, the integrity of the merchandise is verified and it is proceeded to its unloading and preparation for immediate processing.

- Order preparation: Once the merchandise is received, orders are assembled according to the specific needs of the customers. This process includes the selection and grouping of products, as well as the preparation of the necessary documentation for shipping.

- Order distribution: The prepared orders are distributed according to the corresponding routes, ensuring a quick and efficient delivery to the final destinations.

Advantages of cross docking

The implementation of cross docking offers a wide range of benefits for companies, which include:

- Cost reduction: By minimizing the need for storage and handling of merchandise, cross docking helps to reduce operating costs, allowing companies to improve their profitability and competitiveness in the market.

- Greater flexibility and agility: By allowing a faster response to market demands, cross docking helps companies to quickly adapt to changes in market conditions and to remain agile and competitive in a dynamic and changing business environment.

- Space optimization: By reducing the need for storage space, cross docking allows companies to optimize the use of their facilities and reduce the costs associated with inventory storage.

Cross docking in the digital age

In the digital age, cross docking becomes an even more valuable logistics strategy. The growing popularity of e-commerce, the demand for quick deliveries, and the increasing complexity of supply chains make cross docking an indispensable tool for companies looking to stay competitive.

Cross docking at Solistica

Solistica uses cross docking as a key strategy to improve the efficiency of its supply chain. The company has 79 cross docking facilities worldwide, which use the pre-distributed method.

Solistica’s cross docking focuses on the quick and accurate delivery of orders to customers. The company uses a combination of advanced technology and efficient processes to ensure that orders are processed and delivered quickly and safely.

Cross docking revolution

Cross docking is a logistics strategy that is revolutionizing the way companies manage their inventories and deliver their products. By reducing costs, improving efficiency, and providing better service to customers, cross docking can help companies stay competitive in an increasingly challenging business environment.How can cross docking benefit my company?

If your company is looking for a way to improve its logistics efficiency, cross docking may be an option to consider. Cross docking can help your company to:

- Reduce costs: Cross docking can help your company reduce costs associated with storage, handling, and transportation of products.

- Improve efficiency: Cross docking can help your company streamline its logistics processes and reduce delivery times.

- Provide better service: Cross docking can help your company better meet the expectations of its customers, offering faster and more accurate deliveries.

How to implement cross docking in my company?

The implementation of cross docking requires careful planning and coordination among all departments involved. Some key factors to consider when implementing cross docking include:

The necessary infrastructure: Your company will need to have the facilities and equipment suitable for efficiently carrying out cross docking. This includes adequate storage space, material handling equipment, and information and communication systems.

-

- The technology: Cross docking also requires the use of advanced technology, such as warehouse management systems (WMS) and order tracking and tracing systems. This technology helps ensure that the cross docking process is carried out efficiently and accurately.

- Staff training: The staff who will be involved in cross docking will need to receive adequate training to carry out their tasks efficiently and safely.

- Coordination among departments: Cross docking requires coordination among all departments involved in the supply chain, including suppliers, carriers, and customers.

The challenges of cross docking

The implementation of cross docking can present some challenges, such as:

- Initial costs: The implementation of cross docking may require a significant initial investment in infrastructure, technology, and training.

- Complexity: Cross docking is a complex process that requires careful planning and coordination among all departments involved.

- Changes in demand: Cross docking is most effective when demand is constant. Sudden changes in demand can make it difficult to implement cross docking efficiently.

Cross docking is an innovative logistics strategy that offers numerous benefits to companies. However, the implementation of cross docking requires careful planning and coordination among all departments involved. If your company is considering implementing cross docking, it is important to evaluate the potential benefits and challenges involved to determine if this strategy is right for your company.

Here are some examples of how cross docking is being used today:

- In the retail sector, cross docking is used to speed up the delivery of products to stores. This allows stores to offer a better shopping experience to customers, who expect to receive their products quickly.

- In the e-commerce sector, cross docking is used to prepare online customer orders. This allows e-commerce companies to offer faster and more accurate deliveries, which is essential to meet the expectations of online customers.

- In the automotive sector, cross docking is used to distribute parts and components to car manufacturers. This allows car manufacturers to reduce their inventory costs and improve the efficiency of their supply chain.

Cross docking is a logistics strategy that is gaining popularity worldwide. As companies continue to look for ways to improve their logistics efficiency, cross docking will remain a key strategy for companies looking to stay competitive in the global market.